Advanced optical test and measurement services

At TRIOPTICS, we offer industry-leading optical metrology services designed to support your camera and lens projects, no matter the size or complexity. With our US facilities located in Rancho Cucamonga, CA, and Rochester, NY, we provide rapid prototyping, testing, and engineering support to ensure your products achieve superior performance and quality.

Whether you need to diagnose issues with underperforming lenses and cameras or verify the specifications of new models, we offer a full spectrum of testing services to address your needs. We understand the importance of timely results. Our efficient processes ensure that you receive detailed reports promptly, helping you make informed decisions quickly.

Our comprehensive services include

Precision testing & analysis

Prototype manufacturing

Application services

Unique capabilities

Advanced metrology

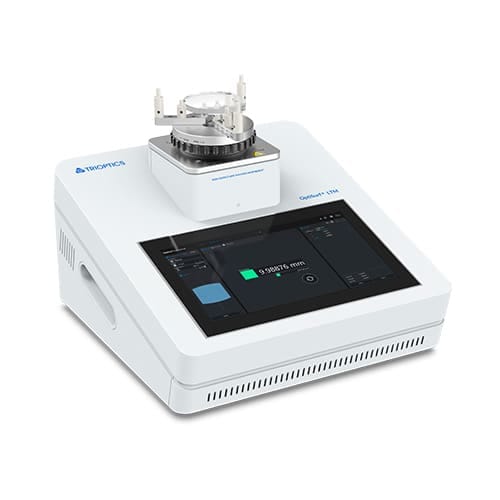

Our labs are equipped with our cutting-edge optical metrology products, ensuring accurate and reliable results.

Technical expertise

We develop camera prototypes & small assemblies, including process optimization, and manufacturing strategy.

Traceability

Calibrated and traceable to national standards, ensuring that your results are accurate, repeatable, and compliant with the highest industry benchmarks.

Worldwide standard

We develop and produce the widest range of optical measurement and manufacturing systems.

Applications

TRIOPTICS offers the world's most comprehensive product portfolio in optical measurement and production technology. We cover the entire value chain of optical manufacturing, from optical components to optoelectronic systems.

Optical component testing

Single optical components are the basic building blocks of optical systems, so it is important that each single component fulfils the quality requirements before it is integrated into a system.

- Angle and Refractive Index

- Tilt Angle, Surface Angle, Pyramidal Angle, Parallelism etc.

- Radius of Curvature

- Focal Length

- Interferometry / Wavefront Measurement

- Centration Measurement

- Beam Deviation

- Lens Thickness Measurement

- Sag*

*Sag height from an annular surface where a plate can be situated

Lens system assembly and testing

The measurement of lens systems plays a key role in both development and production. The accuracy of measurement and alignment is essential to achieve the desired optical parameters, such as high image quality.

- Bonding of Lenses and Assemblies

- Cementing of Doublets, both Manual and Automated

- Center Thickness and Air Gap Measurements

- Interferometry / Wavefront Measurement

- Focal Length Measurement (EFL/BFL/FFL)

- Measurement of Optical assembly alignment

- Alignment turning of optical assemblies

- Beam Deviation

Opto-electronic system testing

Optoelectronic systems play a crucial role in many modern applications. Due to their high complexity and sensitivity, optoelectronic systems require highly accurate assembly and test methods to ensure their functionality and safety.

- MTF on-axis and off-axis

- Effective Focal Length (EFL)

- Through Focus MTF On-/Off- Axis

- Field Curvature

- Lateral and longitudinal chromatic aberrations

- Astigmatism

- Chief Ray Angle

- PSF (Point Spread Function)

- Veiling Glare

- Depth of Focus

- PSF (Point Spread Function)

- Veiling Glare

- Depth of Focus

- Field of View

- Flange Focal Length (FFL)

- Relative Illumination

- Encircled Energy

- Wavefront Measurement

- Zernike polynomials

- Power (sphere, cylinder und addition)

- Orientation of the cylinder axis, orthogonality of the optical axis and deviation of the markers from the optical axis

- Camera Module Testing

Special applications

Temperature testing

Temperature fluctuations can significantly impact the performance of optical systems—affecting alignment, focus, and image sharpness. Testing image quality under varying thermal conditions is essential to ensure your cameras and lenses remain reliable and consistent in real-world applications.

By combining high-precision image quality analysis with controlled environmental testing, we help you verify stability, detect thermal drift, and ensure compliance with safety and performance requirements from prototype to production.

- Effective Focal Length (EFL)

- Flange Focal Length (FFL)

- MTF vs Frequency

- MTF vs Field

- MTF vs Focus

- MTF vs Focus vs Field

- Field curvature

- Distortion

- Depth of focus

- Chief Ray Angle

Active alignment

By providing optimal image quality across the entire field of view, active alignment is an established and efficient manufacturing process to produce high-end camera applications and LiDAR systems. With our help, customers can easily get started in the camera business and optimize their prototypes for later series production.

- Focus

- Shift

- Tilt

- Rotation

Next-generation AR/VR optics

As waveguides become the cornerstone of augmented and virtual reality displays, precise image quality testing is more critical than ever. We provide specialized testing services for even the most advanced and latest waveguide technologies used in cutting-edge AR/VR applications, helping to uncover subtle defects, optical inconsistencies, or alignment errors that could impact user experience.

Our team supports you in identifying the most effective metrology solutions tailored to your unique optical architecture—whether it’s reflective, diffractive, or holographic waveguides.

- On- and off-axis MTF

- Field of view (FOV)

- Eyebox scan

- Chief ray angle (CRA)

- Relative efficiency

- Distortion

- Through-focus scan

- Virtual image distance (VID)

- Depth of focus (DOF)

- Absolute luminance (optional)

- Color (optional)

- Polarization characterization (optional)

Flat optics

Meta lenses represent a new frontier in optical design—ultra-thin, nanostructured surfaces enabling lightweight, compact, and multifunctional imaging systems. Accurate image quality testing is essential to validate performance and unlock the full potential of these revolutionary components.

We offer specialized image quality testing services for the unique challenges of meta lenses, helping you gain access to industry-leading precision without having to invest in complex infrastructure, and ensuring your meta lenses meet the highest standards of optical performance and reliability.

- MTF on axis, off axis ±60°, sagittal and tangential

- EFL / FFL / BFL

- Distortion

- Astigmatism

- Field curvature

- Chromatic aberrations

- Chief Ray Angle

- Relative Illumination

Medical optics

In medical devices, optical performance is about safety, accuracy, and trust. Whether it's endoscopes, intraocular lenses, or contact lenses, even the smallest imperfection can impact diagnostics, treatment outcomes, and patient well-being.

We offer dedicated image quality testing services for a wide range of medical optical components, ensuring that each component meets the stringent quality and regulatory demands of the healthcare industry in compliance with relevant ISO 11979 standards, guaranteeing traceable, repeatable, and industry-accepted results.

- EFL, BFL, Power, add power and cylindrical power

- Toric axis, orthogonality and marker detection

- MTF (LSF), 2D

- MTF (PSF)

- Through focus scans

- Energy distribution, energy loss

- Radius of curvature

Are you interested in an optical measurement service?

Then request your individual offer!

Use our contact form and get quick feedback from our experts. We will be happy to help you!